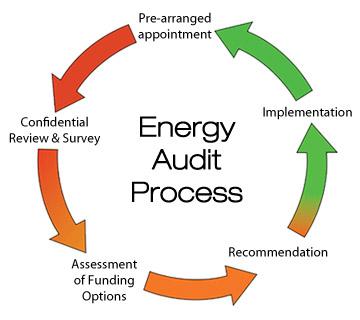

We are now all aware that energy audit or assessment is an inspection, survey and analysis of how energy is used in a building or facility. The sole aim being to conserve energy, achieve optimal efficiency and save costs without affecting the output.

The next relevant and big questions are how do I get started? What I need to do? What do I look out for? What instruments do I require? How do I effectively report the findings for implementation? Getting the job done will guide us to the answers of the above questions

How do i get started and what I need to do

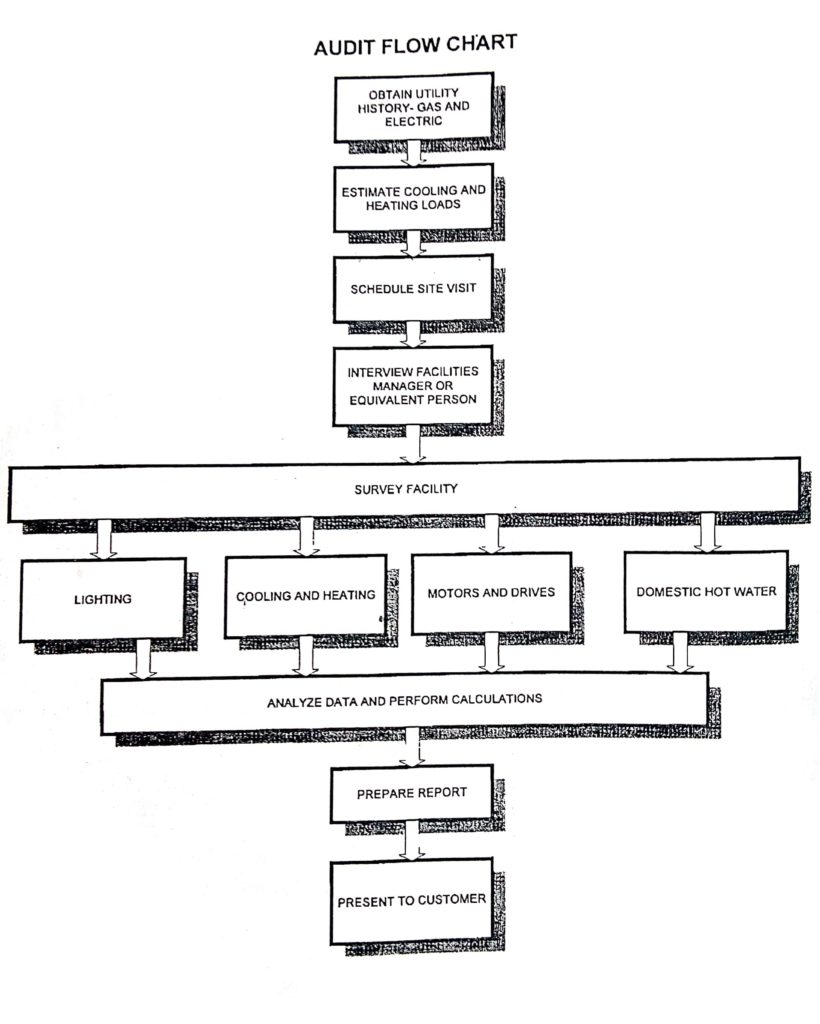

We shall begin with an overview of the processes required in the auditing by capturing the various steps using the audit flowchart below

Step I: Obtain utility History

Here the energy auditors quickly scans the energy usage history of the customer for the last 12-24 months.

Heating and cooling information extracted from the base load, any unusually kW demand peaks noted for further investigation. This gives the auditor an overall feel of the customer’s energy usage. This will be used as benchmark to ensuring recommendations for energy conservation showing realistic energy savings.

Step 2: Estimate cooling and Heating loads

Here the information can be used to estimate the heating and cooling energy consumption.

Base loads are the energy using systems that consume a continuous amount of energy throughout the year. The base loads can be established by drawing a horizontal line across a graph of energy consumption or cost at the average point of lowest consumption for each energy type. The base load is that portion of consumption or cost below the line as shown in the figures below. Typical base loads include lighting, office equipment, appliances, domestic hot water and ventilation. High base loads indicate that conservation efforts should be focused in these areas

High base loads indicate that conservation efforts should be focused in these areas.

Steps 3 and 4: Site visit and interview

A site visit is then scheduled, and the facility energy manager or knowledgeable operator interviewed. The meeting and interview session yields valuable information as to the customer’s energy usage and equipment.

The operator/facility manager should be familiar with the building or plant operation and equipment. The discussions shall center and give information among others to the following:

- Verify meter number and account information

- Building square footage

- Operating hours

- Equipment operating hours

- Equipment sizes and age

- Motor lists

- Conservation measures planned or done

- Energy concerns

- Payback/financial criteria

- How are they handling the CFC/HCFC phase-out

- New or planned equipment changes

- Energy management system

- Data centers

- Expansion plans

- Attitudes toward energy conservation

- Maintenance practices

- Building ownership

- Occupancy

- Utility rate concerns

- Interest in renewables/distributed generation

Step 5: Facility survey

This is the soul of the audit. The facility is surveyed for the key energy consuming areas. Depending on the level of audit, facility size and complexity, the audit time can range from a few hours to weeks or more. The important areas to consider are:

- Building envelope

- HVAC System

- Electrical Supply System

- Lighting

- Boiler and Steam System

- Hot Water System

- Compressed Air System

- Motors

- Special Purpose Process Equipment

- Water and sewer system

Prior to the survey, ask to see if they have the working drawings and designs, as built and single line drawing of the building and MEP installations . These drawings provide you with the following information on motors, chillers, compressors, electric heaters, lifts, boilers, air handling units etc. May vary depending on the audit type, namely: home, commercial or industrial audit.

You should also gather information on the nameplates that will give an idea of age, capacity, tonnages, year of manufacture, horsepower and efficiency etc of various equipments.

However, depending on the level of audit, measurements and verifications (M & V) will be done with the appropriate instruments.

The remaining steps of the auditing process: data analysis and calculations, report preparation and energy audit equipment list shall be discussed in the next post Getting the job II. Watch out

Contact us

Victor Oyedu, FNSE, FNIEEE, CPQ.

Power Quality and Energy Management Specialist.

Publisher at Afrienergyonline.com &

CEO, FullSpectrum Energy Solutions Limited, Nigeria