Today, we shall be talking on the general characteristics of lighting systems. The key indicators that shall help us understand the lighting designs, specifications, guidance in the upgrading and retrofitting lighting systems for optimal efficiency.

Lighting Efficacy

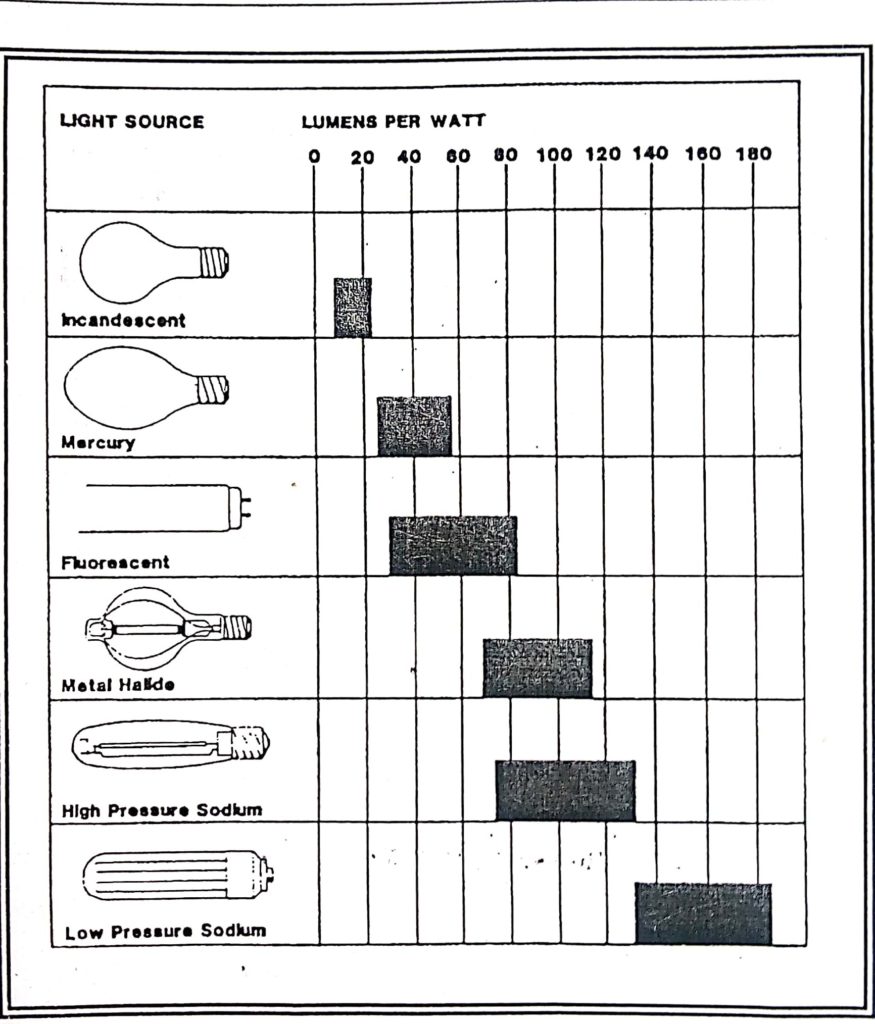

The efficacy of a lamp is expressed as the ratio of its light output over the energy input. The light output is expressed in lumens and the electrical input in watts. The resulting value is expressed in lumens per watts (lpw).

Noted that the wattage used in the lpw (lighting efficacy) figure usually does not include wattage required for the ballast.

Efficacy Ranges

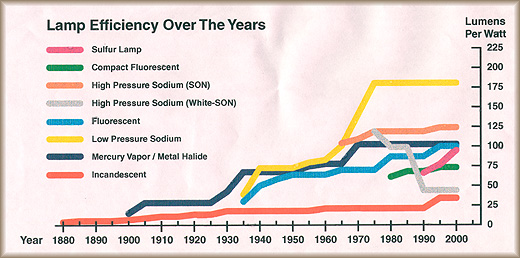

Incandescent lamps generally have efficacies in the range of 10 to 20 lpw. Mercury vapour lamps have efficacies that range from 25 to 55 lpw, or more than twice the incandescents. Incandescents have efficacies that range from 30 to 80 or more lpw.

While the metal halide lamps are up to 115 lpw. High pressure sodium lamps exceed 120 lpw, and some low pressure sodium lamps can reach in excess of 180 lpw. These efficacy figures are illustrated below.

Note: LEDs currently have efficacies that range from 30-100 lpw. Efficacies for white LEDs greater than 200lpw have been achieved and currently finding their way to the market place.

The lumens per watt for induction lighting currently, are in the 70-80 lpw range. Below shows the efficacy in lpw for various lamp types.

EISA Standard Incandescent Phaseout (U.S).

Most first world nations have phased out or phasing out inefficient incandescent lamps.

The Energy Independence and Security Act of 2007 (EISA), in the United States of America had phased out inefficient incandescent lamps by 2014. The phase out plan was as follows;

- 100W inefficient incandescents in 2012

- 75W inefficient incandescents in 2013

- 40W and 60W inefficient incandescents in 2014

The EISA 2007 also impacts other types of lighting including T-12 fluorescents, mercury vapour, metal halides as well as ballasts

The law has many rules and many exceptions; it is suggested that the actual law be reviewed in details and readily obtainable on the internet. This information is readily obtainable on the internet.

BALLASTS

All the lamp types previously mentioned except incandescents require what is called a ballast to operate. The ballast provides the high voltage required to strike an arc that starts the lamp, and regulate the power going to the lamp. The older ballasts were electromagnetic and less efficient, adding 15 – 20% to the lamps wattage just to run the ballast.

Electronic ballasts are lighter, quieter and cooler than their electromagnetic counterpart. Electronic ballasts however inject harmonic distortions on the electrical system. It is suggested that to minimize these distortions. Use of electronic ballasts rated at 10% or less THD (total harmonic distortion) is recommended.

LIGHT COLOUR

The primary rating system for evaluation, the “colour” of light is called the Colour Rendering Index or CRI.

The CRI is a rating system between 0 and 100 which describes how well a light source brings out the true colour of an object under reference lighting source.

A typical incandescent bulb has a CRI of 99, whereas a warm white fluorescent has a CRI of 52. The high and low pressure sodium lamps have poor colour rendition, typically in the range of 1 to 20. Care should be taken when recommending lighting changes that the CRI level is acceptable to the business.

Correlated Colour Temperature

Another parameter is the Correlated Colour Temperature or CCT, measured in degrees Kelvin. It is a measure of the colour appearance of a light source which helps describe the apparent “warmth” (reddish) or “coolness” (bluish) of that light source.

Generally, light sources below 3200K are considered “warm”; while those above 4000K are considered “cool” light sources. The colour temperature of a lamp has nothing to do with how hot the lamp will get or how much heat will be given off by the lamp.

The most typical Kelvin degree lamps used in lighting are as follows:

| Kelvin | Associated Effects & Moods | Appropriate Applications |

| 2700° | Friendly, Personal, Intimate | Homes, Libraries, Restaurants |

| 3500° | Friendly, Inviting, Non-threatening | New Offices, Public Reception Areas |

| 4100° | Neat, Clean, Efficient | Older Offices, Classrooms, Mass Merchandisers |

| 5000° | Bright, Alert, Exacting Colouration | Graphics, Jewellery Stores, Medical Exam Areas |

Lamp Lumen Depreciation (LLD)

The amount of light produced by most lamps decreases with age, while energy consumption remains constant.

This characteristic is referred to as lamp lumen depreciation, or LLD. This can also be referred to as lumen depreciation and affects some lamps at a much faster rate than others. The T-8 fluorescent lamp (T-5) is similar and tends to hold its output the highest when compared to the other types of lamps as seen below . LEDs and induction lighting are shown also.

In all cases, however, efficiency declines with the age of the lamp. Since the lighting levels of the lamps of similar type, lights tend to depreciate at the same rate, it is a good idea to change out all similar bulbs in a facility at the same time.

This group re-lamping, common with fluorescents, is a good maintenance policy as it ensures that lighting levels do not go below minimum design specifications after a certain number of operating hours.

Contact us

Victor Oyedu, FNSE, FNIEEE, CPQ.

Power Quality and Energy Management Specialist.

Publisher at Afrienergyonline.com &

CEO, FullSpectrum Energy Solutions Limited, Nigeria