Wiring and Earthing (Grounding) are essential power quality (PQ) tools used in energy management.

The use of best practices in wiring and grounding (earthing) ensures safety, prevents fire hazards and importantly allows a piece of equipment to function in its intended manner without significant loss of performance and life expectancy.

It improves efficiency and quality of operations, reduces costly downtime, thereby the entire operational and maintenance costs. Hence, the prefix performance

Grounding (Earthing) & Wiring are foundational and critical to ALL electrical power, communication or data processing systems infrastructure.

With Over 80% of power quality (PQ) problems traceable to improper wiring and grounding of systems. It is key to addressing these subjects professionally and meticulously well in advance.

Obviously, the least costly solution to power quality problems, instead of the more expensive option of purchasing and installing power conditioning equipment. A purely fire brigade approach.

Most facilities are wired and grounded to national standards and codes like, BS 7671 (IET wiring regulations), International Electrotechnical committee (IEC), National Electric Code (NEC) etc, at the expense of best practices that ameliorate workplace power quality concerns

A more cost-effective approach is to correct the root cause of the problems at the early stage instead of attacking the symptoms.

Power quality problems arise from loose connections, small sized neutral conductor, incorrect grounding, or a damaged conductor.

We shall now, look at basic wiring and grounding principles, with the power quality lens.

Wiring Principles

The three vital principles of wiring are:

- Keeping the length of the wire to a minimum to avoid unnecessary voltage drop on the conductor.

- Connecting wires solidly to panels and switchboards

- Sizing and selecting the conductors to match the current-carrying capacity of the load.

All these three principles try to minimize the conductor and connector resistance.

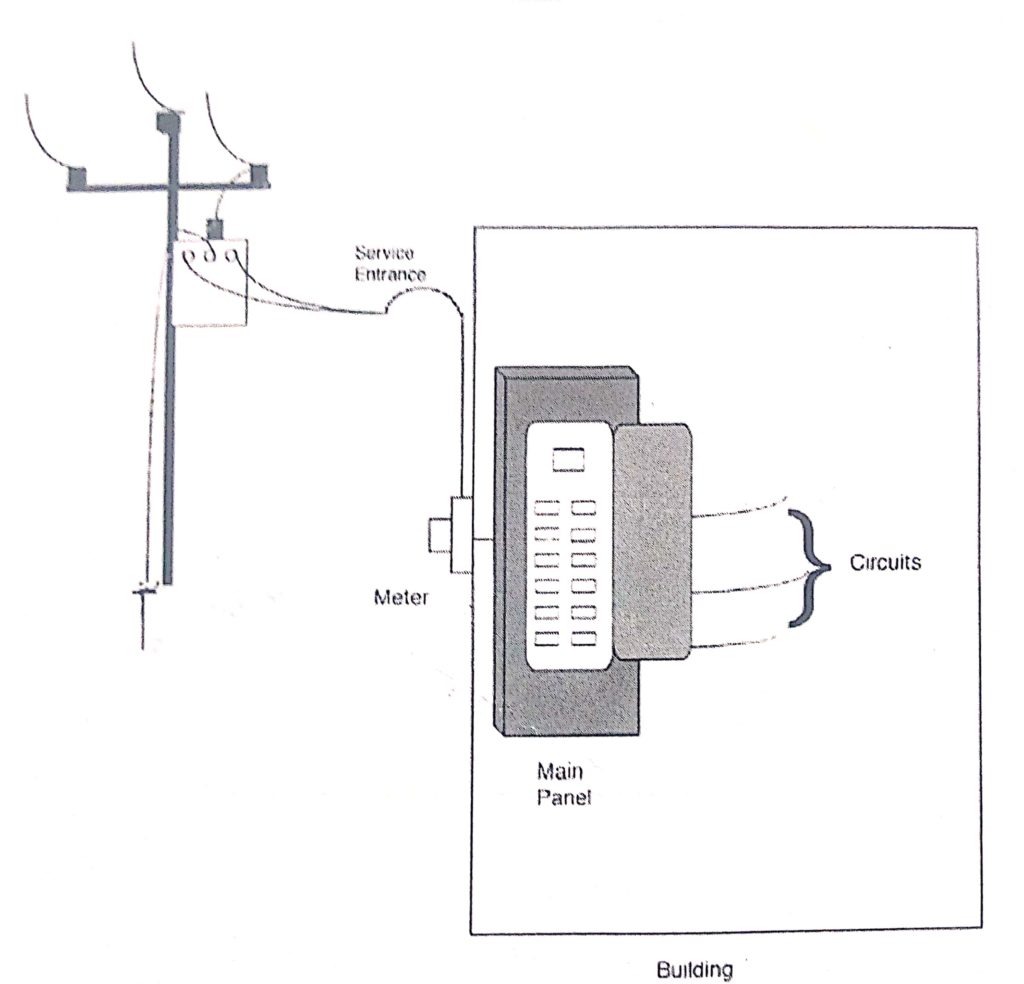

They apply to both the end user’s home as well as to a utility’s high-voltage transmission and distribution lines. For example, a residential or small commercial facility has a main panel board to distribute power to the various circuits inside, as shown below

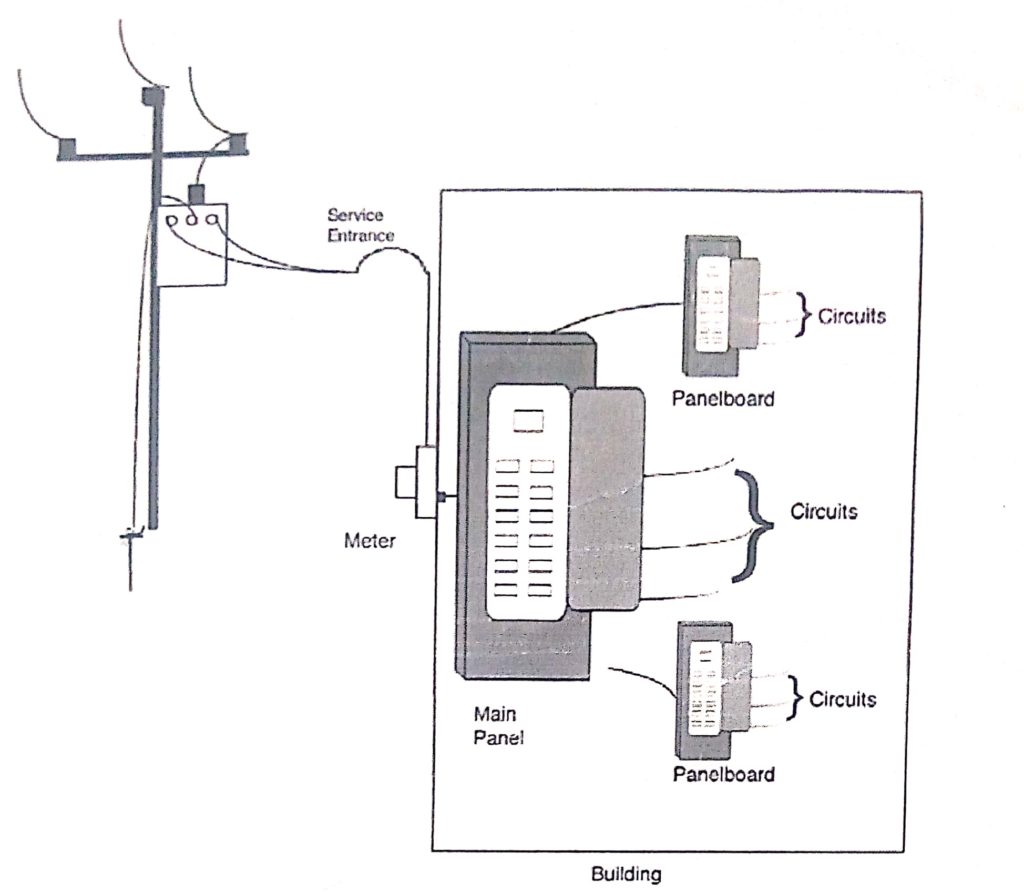

While the industrial or large commercial facility has not only a main panel board but also several branch panel boards, as shown below

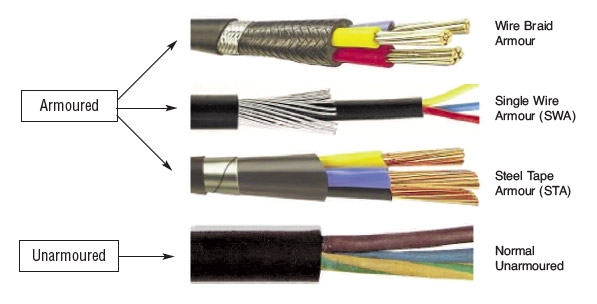

End users and utilities select conductors that are the most cost-effective. Most industrial, commercial, and residential end users use copper conductors in their internal electrical distribution systems.

While Utilities, for cost effectiveness use aluminum conductors in high-voltage transmission, low-voltage distribution lines.while aluminium conductor steel reinforced (ACSR) are for larger conductors. Below shows typical ACSR conductors atop transmission lines.

Grounding (Earthing) Principles

Proper grounding is critical to the safe and effective operation of all electrical equipment.

Grounding (Earthing) means connecting an object or electric circuit to ground or earth with an electrical conductor. The object is usually a piece of equipment.

The electric circuit refers to the utility’s transmission, distribution or the end user’s power distribution systems. Extending to telecommunications operator’s and end user’s systems.

The symbol for grounding is

The purpose of Grounding which is basically a health, security and environment (HSE) concern are;

- Protecting people from electrical shock & equipment from short-circuit faults

- Providing zero reference point

- Providing for Noise control

- Providing path for lightning and switching surge faults

Contact us

Victor Oyedu, FNSE, FNIEEE, CPQ

Power Quality and Energy Management Specialist.

Publisher at Afrienergyonline.com &

CEO, FullSpectrum Energy Solutions Limited, Nigeria