In this section, we shall look at the major types of lighting used in facilities.

The lamp’s construction, general strengths, weaknesses and improvement opportunities.

This knowledge when applied shall be a veritable tool in achieving lighting system efficiency thus saving money.

Incandescent lamps

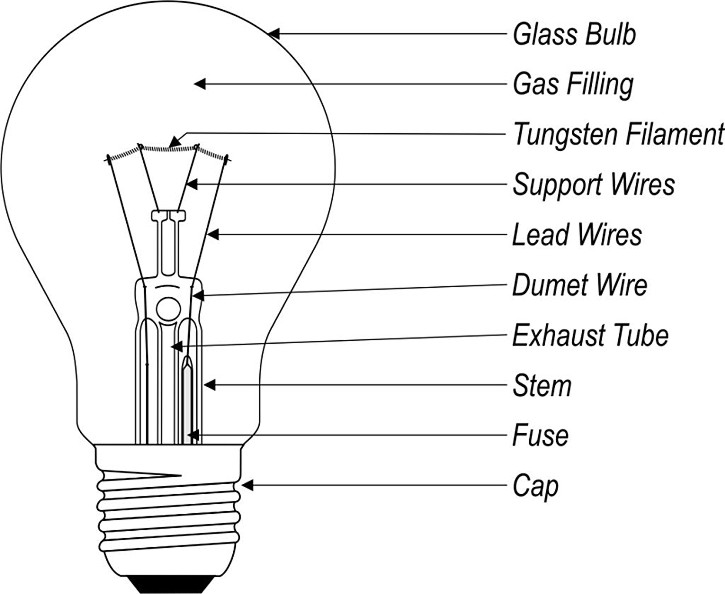

The basic incandescent is as shown below. Electricity is passed through a filament, typically tungsten, which emits light and heat. The filament is operated in a vacuum which prevents it from quickly burning up. This design is basically Edison’s “wire in a bottle design”.

Incadescent lamp

Strengths

- Low cost

- Easily dimmable

- Wide variety of selections available

- Instant starting

- Warm colour

- Small compact size

- Requires no ballast

- Excellent colour rendition

- Simple to install and operate

Weaknesses

- Very inefficient source of light (< 10% of the energy is converted to light).

- Relatively short life (750 to 3500 hours) which decreases with over voltage.

- High heat component contributes to air conditioning load.

Improvement Opportunities

- If incandescent lighting is a must, then consider replacing bulbs with tungsten halogen equivalents. They have longer lives (up to 12000 hours) than typical incandescents and have much better lamp lumen depreciation.

- Install compact fluorescent or LED lighting.

FLUORESCENT TYPE

Fluorescent lamps are the second most common type of lamp used in commercial buildings. On the average, fluorescents convert 20% of the input energy into useful light.

These lamps work by a process called gas discharge.

An electric arc, provided by the ballast, is required. Once this electric arc is established, the ballast acts to regulate the current in the tube.

Phosphors coated on the inside of the glass tube react with the arc to produce light. The lamp contains a filling gas such as argon, and a small amount of mercury. The mercury in the lamp dictates that proper disposal methods be followed.

Components of a Fluorescent Lamp

Fluorescent Systems T-8 and T-5

T-8 fluorescent systems are an excellent option for a facility that needs to replace lamps and ballasts. The standard fluorescent lamps are called T-12, the “12” representing the number of 1/8 inch increments for the tube diameter. A T-12 lamp is therefore 1.5 inches in diameter.

The T-8 lamps are smaller and more efficient than the T-12s, having a diameter of 1 inch. The T-8 lamp uses more costly phosphors to coat the inside of the tube.

These phosphors, coupled with the electronic ballasts, produce a very efficient fixture. For example, a standard fluorescent fixture with T-12 bulbs operates at about 1.5 watts per square foot of building space. A T-8 fixture operates at about .8 watts per square foot. The T-8s will fit in existing T-12 fixtures.

T-5 lamps are also available, but typically require that the existing fixtures be replaced due to the different pin spacing. The use of T-5 lamps in high bay applications is now on the increase.

T-8 Lamp vs T-12

Compact Fluorescent Lamps (CFLs)

CFLs are available in various wattages and can replace most incandescent bulbs. In the US, the incandescent bulbs that do not meet efficiency standards had been phased out since January 2014.

Most CFLs and LEDs meet these standards.

Compact Fluorescent

Fluorescent Lamp Strengths

- Four times more efficient than incandescent

- Long-life. 10 to 20 times that of incandescent

- Low lamp cost

- Available in a wide variety of sizes and colors

- Less heat generated than incandescent

- Easily maintained

Weaknesses

- With the exception of compact fluorescent lights, most fluorescents are large and require relatively expensive features

- Electromagnetic ballast tend to hum and adversely affect power factor

- Electronic ballasts create harmonic distortion on the power system

- Lamps are dimmable, but require electronic ballast and controls

- Lamps may be difficult to start in low temperature situations

Improvement Opportunities

- Utilize CFLs or LEDs wherever possible to replace incandescents

- Convert existing T-12 fluorescent systems to T-8 or T-5 systems

- Evaluate T-8 or T-5 high bay lighting

- Consider using reflectors and de-lamping existing fixtures

MERCURY VAPOUR LAMPS (Hg)

Mercury vapour lamps belong to the family of gaseous discharge lamps which produce light due to an electric current flowing through a vapour atmosphere.

Mercury lamps are also classified as high intensity discharge lamps (HID). These lamps operate at a relatively higher pressure than the near vacuum of fluorescent tubes. These lights are typically used in outdoor applications.

Mercury Vapour Lamp

Mercury Vapour Lamp Strengths

- More efficient than incandescent, but less efficient than fluorescents

- Lamps available in a wide variety of ratings, sizes and shapes

- Relatively low initial costs

Mercury Vapour Lamp Weaknesses

- The most inefficient source of lights next to incandescent

- Poor LLD compared to other HID lamps

- Requires a 5 to 7 minute warm-up period

- They have a distinctive bluish cast (poor CRI)

- They require a 4 to 5 minute cooling and restart time

- They require a ballast

Improvement Opportunities

- Replace mercury vapour lamps with metal halide lamps when colour is an issue

- Replace mercury vapour lamps with high pressure sodium lamps if colour is not important

- Evaluate high bay fluorescents

Contact us

Victor Oyedu, FNSE, FNIEEE, CPQ.

Power Quality and Energy Management Specialist.

Publisher at Afrienergyonline.com &

CEO, FullSpectrum Energy Solutions Limited, Nigeria