Electric Motors consume over 60% of the Energy used in industries. They are found in almost every piece of equipment, from process, manufacturing, mining, agriculture and special operations like the chillers and air compressors etc.

Apart from the obvious advantages, they are costly to operate if not properly selected and maintained.

With widespread applications in almost every facility, they are prime candidates for improvements in machine utilization.

A small improvement in the Electric Motor Efficiency can produce significant energy savings of the operating piece of the equipment.

The annual operating cost of a motor can be upto 10 times the original purchase price of the motor.

Careful selection and understanding of motor nameplate is indeed critical.

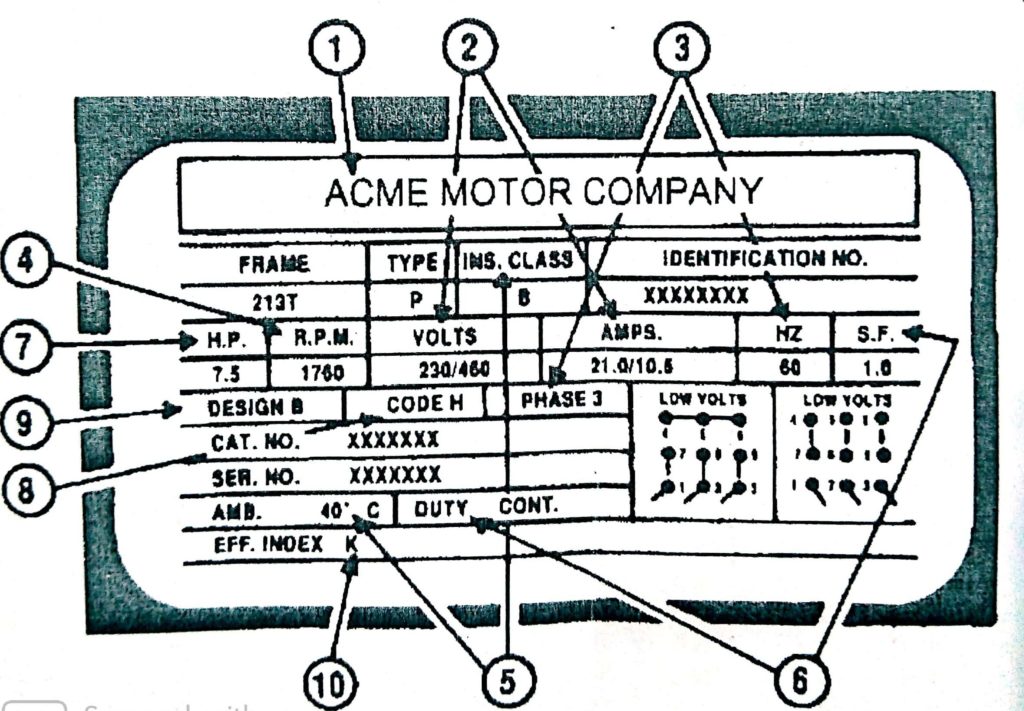

Nameplate information

The following items are typically on the motor’s nameplate. Some of the items, for example, efficiency rating, would not appear on older motors.

*Manufacturer

*Rated voltage

*Full load amps

*Frequency

*Phases

*Rated full load speed

*Insulation class

*Ambient temperature

*Service factor

*Rated HP

*Locked rotor Code

*NEMA design

*Efficiency index or value

*Bearing sizes

The nameplate does not show the number of poles, slip or the synchronous speed. However, this information can be extrapolated from the name plate.

Note: Nameplates on operating motors often are difficult to read, due to age, paint, grease or sometimes because they are not there at all.

Typical Nameplate

Legend

- Name of Manufacturer

- Rated voltage – it can be single 230V or three phase 460V and full load amps is 21/10.5 respectively

- Rated frequency and number of phases

- Rated full load speed in RPM

- Rated temperature rise and insulation class

- Service Factor

- Horsepower rating

- Locked Rotor Code (Can be used to determine starting current)

- National Electric Motor Association (NEMA) design (A,B,C or D)

- Efficiency number or letter (Neither will be on older motors)

Other parameters commonly found on motor nameplate that we have not previously defined include;

- FLA – Full Load Amps – The line current the motor draws at full load.

- LRA – Locked Rotor Amps – This is a test value for the motor but it is useful for knowing the maximum starting current surge into the motor.

- Service Factor – A factor on the nameplate horsepower of the motor. This tells how much overload the motor can safely handle on a short term basis.

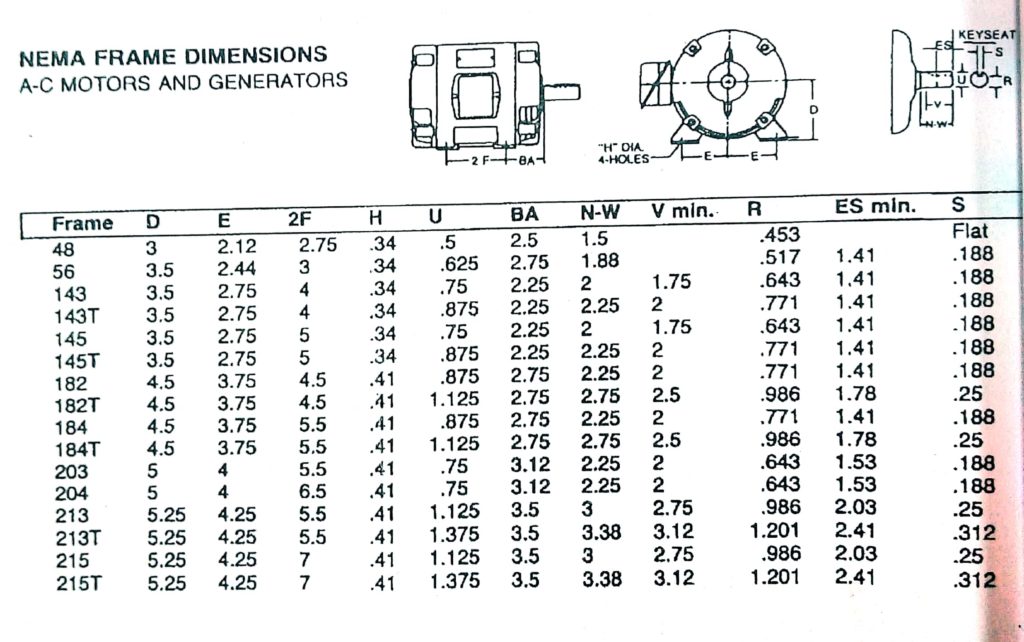

The motor Nameplate can be read together with the NEMA frame dimensions shown below

In Motor Energy management, it is an established fact that a motor annual operating cost is by far greater than the initial purchase price of the motor, often between 5- 10 times

At FullSpectrum Energy, we understand this and other Energy saving techniques that help facilities select and maintain premium Electric Motors, that are fit for Purpose, Optimally Efficient and cutting down Operational Cost.

Solutions are available

Victor Oyedu, FNSE, FNIEEE, CPQ.

Power Quality and Energy Management Specialist.

Publisher at Afrienergyonline.com

CEO, FullSpectrum Energy Solutions Limited, Nigeria.