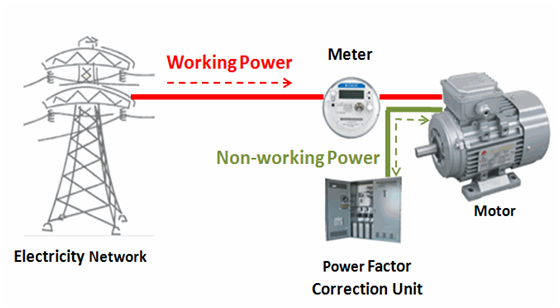

Power factor is a critical issue in commercial and industrial establishments. The proper management of power factor for organisations, saves money, enhances operations, extends life expectancy of machinery and saves utility penalties.

From the electricity utility perspective it frees up energy for other customers and reduces pressure on electrical infrastructure. It is therefore a power quality and energy management tool in optimizing operational costs. Electric utility companies charge for kilowatt hour and demand charge in KVA.

What is power factor?

Power factor is the ratio of the real or active power that does the actual work in kilowatts and the apparent power in kVA drawn. A unit of power systems efficiency.

Graphically,

NOTE: kilowatt is the power that does the active work and kVAR is the power that creates magnetic flux in transformers, motors, relays etc while KVA the apparent power is the vector sum of both the reactive and active power.

Here is a simple analogy.

The Beer analogy

It is unusual to have a beer without foam, and the quality of beer is inversely proportional to the foam generated. That is why beer manufacturers strive to reduce the amount of foaming in beer.

In power systems you cannot supply power without kVAR. For this reason power factor always approaches unity but never equal to unity.

Electrical circuits have inherent capacitive and inductive characteristics that introduce reactive power requirements. This reactive power is required by an AC electrical system to set up magnetic fields for transfer of power from the primary to secondary windings of machines.

Power factor is caused by transformers, motors, HID lamps, arc furnaces and rectifiers. Usually expensive for both customer and the utility company in the sense that more energy is dissipated.

Consider a 100kW motor with a power factor of 0.6 against same but with power factor of 0.95. The apparent powers drawn are as follows

kVA = kW/PF

100kW/0.6 = 166.6kVA

100kW/0.95 = 105.26kVA

It is obvious that the same motor with 0.6 power factor will draw about 66.6% more power to drive a 100kW motor from utility while an improved power factor of 0.95 will only draw about 5% more.

As the end user pays more, there is pressure on the utilities electrical infrastructure that translates to bigger sized cables, switch gears, transformers etc. Therefore the power factor penalty must apply.

Benefits of correcting low power factor

- Immediate cost savings and reduction of energy bills

- Saving penalties from utilities.

- Reducing heat in equipment.

- Increasing equipment life expectancy

- Reducing Energy losses and operating costs.

- Freeing up available energy for other users.

- Reducing voltage drops in the electrical system.

- Reducing the carbon footprint.

Power factor improvement

There are two ways to improve power factor and minimize the apparent power drawn from the source.

- Reducing the lagging reactive current demand to loads.

- Compensating for the lagging reactive current by supplying the leading reactive current to the power system.

In a typical power system, no devices require leading reactive current to function; therefore to produce leading currents certain devices must be inserted in the power system. These devices are referred to as power factor correction equipment. The benefits of correcting low power factor include;

- Saving penalties from utilities.

- Reducing heat in equipment.

- Increasing equipment life expectancy

- Reducing Energy losses and operating costs.

- Freeing up available energy for other users.

- Reducing voltage drop in the electrical system.

FullSpectrum Energy, will help organisations improve their facility power factor, save money, increase life expectancy, enhance the overall health of the systems necessary for sustainability to enhance bottom line.

Contact us

Victor Oyedu, FNSE, FNIEEE, CPQ

Power Quality and Energy Management Specialist.

Publisher at Afrienergyonline.com &

CEO, FullSpectrum Energy Solutions Limited, Nigeria.