If your transformers, cables and neutrals overheat. When you experience voltage sags (dips), swells (overvoltages) or sudden increase in voltage in form of spikes, transients, glitches, surge and voltage unbalance among phases.

Circuit breakers tripping, computer shutting down, high temperature in server rooms, motors burning, PLC misoperating or light flickering, you have a power quality problem.

A good power quality for equipment A, may be poor PQ for equipment B.

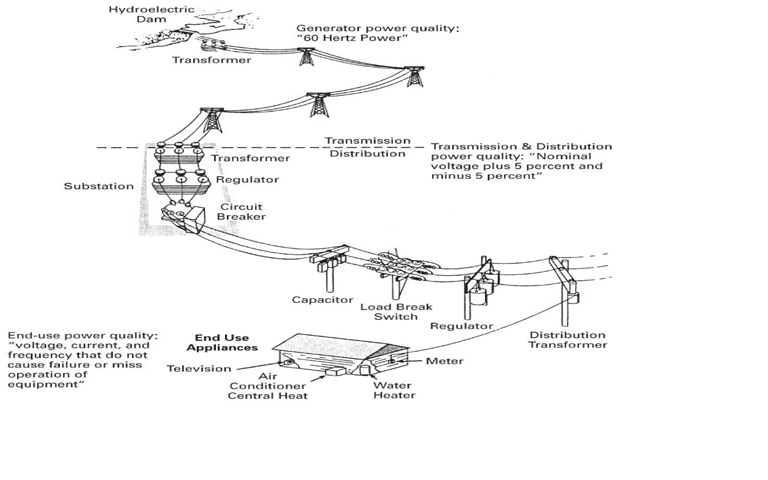

PQ – A matter of perspectives

In power generation, if the frequency is not stable.

The nominal voltages on the transmission and distribution lines have regulation of more than ± 5%.

The end-user or customer experiences voltage, current and frequency that cause equipment to fail or misoperate.

The issue is poor PQ. Therefore PQ depends on your perspective and equipment. What then is PQ?

Power Quality Defined –

There are many definitions in various electrical/electronics textbooks, IEEE, NEPA and engineering handbooks etc.’

However, IEEE defines PQ as “the concept of powering and grounding electronic equipment in a manner that is suitable to the operation of the equipment and compatible with the premise wiring systems and their connection equipment” (IEEE std 1159-2009 recommended practice for monitoring electric power quality)

Power Quality problem can be defined as any power issue manifesting in voltage, current or frequency deviations that result in failure or misoperation of utility or end user equipment (Ref-Technical power system quality Roger Dugan Mark McGranagham and wayne Beaty).

At FullSpectrum we subscribe to the definition below that emphasizes performance and equipment life:

Power quality therefore is a set of electrical boundaries that allows a piece of equipment to function in its intended manner without significant loss of performance and life expectancy.

What the equipment want

What Equipment Gets

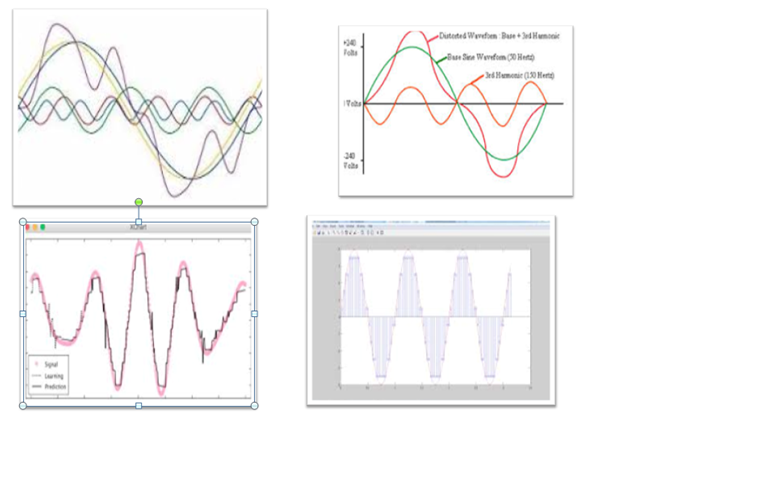

The spectrum of PQ has assumed unprecedented dimensions with the proliferation of electronics in today’s industry. Though enhancing efficiency and optimization of processes and systems, they however inject PQ problems with its attendant consequences and cost.

Cost of poor PQ

The consequences of various systems add complexity to PQ issues. Computers are working fine but network is bad, nobody can pay hospital or utility bills or book a flight.

In a facility, the process is operating correctly but HVAC has shut down. Production must stop. Such mission critical systems exist throughout facilities.

When you consider the factors of production in any plant, labor, material and time. Time is the only variable. Therefore you must be efficient and optimize operations via automation to get more output from same inputs.

Automation relies on “clean” power and PQ problems cause processes and equipment to malfunction or shutdown.

The cost of poor PQ is much ranging from loss of productivity and business to complete data damage and early failure of equipment.

The power interruption cost is calculated with the following inputs

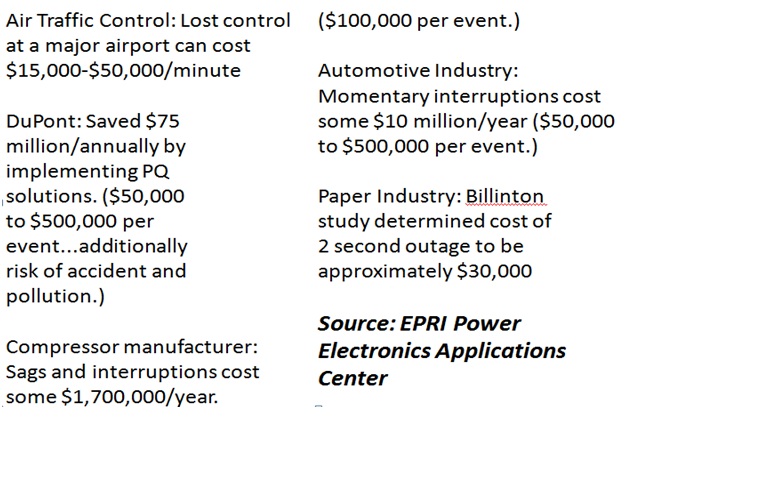

With the above input one can estimate and calculate in various sectors as shown below

Electric Power Research Institute (EPRI) in 1995 reported that the effect of poor PQ in US represents a large annual cost to the economy estimated at the cost of 100 billions of dollar (US$100 Billion)

While the Leonardo energy/European copper institute in a study in 2007, shows that poor PQ affected businesses in the industrial and service sectors totaling EURO150 billion in EU-25.

Unfortunately expenditure on preventive maintenance is less than 5% of Euro 150b, calling for more expenditure and efforts in cutting down the cost of poor power quality.

In Nigeria, however the loss of productivity due to poor power quality issues is high and rising exponentially. Though events are not recorded doesn’t mean they are not there. While other countries talk of interruption in seconds and minutes. Nigeria and indeed underdeveloped countries, sorry “developing countries” are talking of complete interruptions in hours and days. Complete black-out in weeks, months and even years. Hence making nonsense of productivity.

What are then the sources of power quality problems and what is its scope?

See Power Quality – an overview III

Contact us

Victor Oyedu, FNSE, FNIEEE, CPQ.

Power Quality and Energy Management Specialist.

Publisher at Afrienergyonline.com

CEO, FullSpectrum Energy Solutions Limited, Nigeria.