Industrial and commercial work environment are plagued by various power quality phenomena in today’s work space as a result of proliferation of electronics.

These electronics drive the work processes and systems are usually affected by power quality issues in other words deviations in voltage, current (power quality), frequency.

Among these power quality phenomena the one mostly wrecking havoc in facilities are voltage sags and swells.

Voltage sags and swells are the most prevalent power quality parameters that disrupt, cause damage, costly downtime and affect viability of organizations.

Understanding these two PQ events, what they are, their causes, signature, impact in industries and mitigation techniques are vital performance, reliability and efficiency of most business concerns.

What are Voltage Sags and Swells?

Voltage Sags

Also known as Voltage Dips, occur when the voltage in an electrical system drops to 10-90% of its nominal level for a duration of one-half cycle to one minute.

These are short-term decreases in voltage magnitude can be caused by various factors.

Voltage Swells

On the other hand, are short-term increases in voltage, typically between 110% and 180% of the nominal level, lasting from a few milliseconds to a few seconds.

Sags and Swells have significant impacts on electrical equipment and industrial processes.

How prevalent is Voltage Sags and Swells events in facilities?

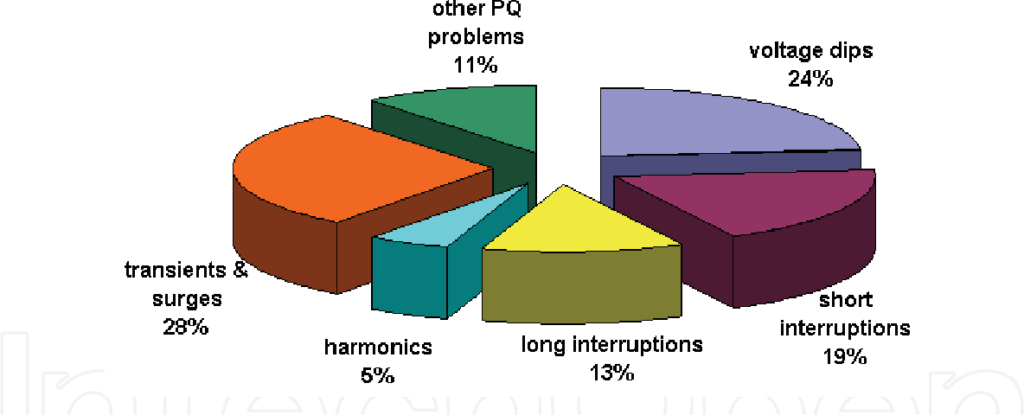

Among power quality issues, voltage sags and swells are among the most occurring events.

Studies suggest that they account for up to 30% of all power quality problems in some industries.

Depending on can the local power grid, industry type, and geographical location.

What are the causes of Voltage Sags and Swells?

Voltage sags are often caused by:

1. Faults on the utility system such as short circuits or ground faults.

2. Switching of large loads within an industrial facility.

3. Starting of large motors, which draws significant current and cause a temporary drop in voltage.

Voltage swells are typically the result of:

1. Sudden reduction in load on a power distribution system.

2. Switching off a large power factor correction capacitor.

3. Faults in the utility system particularly open circuit faults.

How do they manifest in work environment?

Voltage sags and swells can manifest as;

A. Flickering lights,

B. Computer resets,

C. Machinery malfunctions

D. Shutdowns of sensitive equipment.

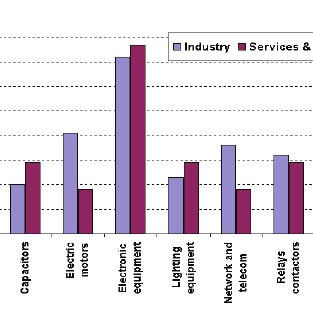

Impacts across industries may include the following:

A. Data Loss.

Computers and servers may shut down unexpectedly, leading to loss of unsaved work and potential data corruption.

B. Equipment damage.

Sensitive electronic equipment can be damaged by overvoltage conditions, leading to costly repairs or replacements.

C. Downtime.

Production lines may halt, causing delays in manufacturing and potential breaches of contract due to missed deadlines.

D. Reduced lifespan of electrical components.

Frequent voltage fluctuations can reduce the operational lifespan of motors, drives, and other electrical components.

These impacts can erode business’s competitiveness by increasing operational costs, reducing productivity, damaging customer trust and the bottom line.

How then can these events be mitigated?

Mitigating voltage sags and swells, businesses can deploy these strategies depending on the power quality survey:

A. Voltage Regulators

Regulators automatically adjust voltages to a stable level, protecting sensitive equipment.

B. Uninterruptible Power Supplies (UPS).

UPS provide immediate power backup during voltage sags and maintain stable voltage during swells.

C. Surge Protectors.

Prevent degradation, disruption and damage from voltage swells by diverting the excess voltage away from sensitive equipment.

D. Power Conditioners

Power conditioners smooth out the power supply, ensuring that equipment receive consistent voltage level.

E. Proper Grounding and Bonding.

Ensure that the electrical infrastructure is properly grounded and bonded for stability, reliability and resilience. This is the bed rock of all power quality issues

Mitigating voltage fluctuations electrical noise, surge protection and generally providing signal reference ground for sensitive electronic equipment.

Don’t let voltage sags and swells undermine your business’s performance and overall competitiveness.

At Fullspectrum, we deploy best practices in power quality and energy management through bespoke trainings and offering cost effective solutions to businesses.

Saving money, safeguarding critical assets, being more productive, efficient and enhancing overall business competitiveness are the clear results.

A stitch in time saves more than nine

Whatever, wherever, and whenever the challenges, Fullspectrum solutions is just a click or a call away

Contact us to schedule trainings and power quality assessment today!

Power Quality and Energy Management Specialist.

Publisher at Afrienergyonline.com

CEO, FullSpectrum Energy Solutions Limited, Nigeria.