Power quality (PQ) is significant to survival, success and failure of most businesses.

It has become a safety and key financial consideration, that determine productivity and efficiency of facilities.

PQ issues ravage workplaces leaving a trail of dire consequences.

Some could be quite severe, depending on the nature of the business and the sensitivity of the equipment in use.

The potential consequences can wreck the following havoc;

1. Equipment Damage.

Sensitive electronic equipment can be damaged by voltage spikes, surges, and transients. This can lead to costly repairs or replacements and potential downtime.

2. Data Loss or Corruption.

Unstable power can cause computers and servers to shut down unexpectedly, leading to loss of unsaved data or even corruption of existing data.

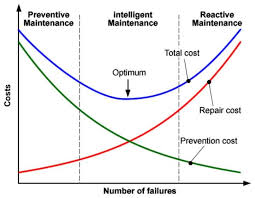

3. Increased Maintenance Cost

Frequent power quality issues can lead to increased wear and tear on electrical components, resulting in higher maintenance costs and reduced equipment lifespan.

4. Operational Downtime.

Interruptions in power can halt production lines, cause office downtime, and disrupt normal business operations, leading to lost productivity and revenue.

5. Reduced Efficiency.

Harmonic distortion and other power quality issues can reduce the efficiency of electrical equipment, leading to higher energy consumption and costs.

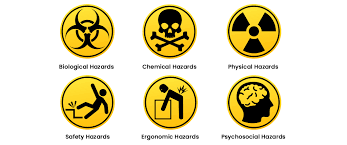

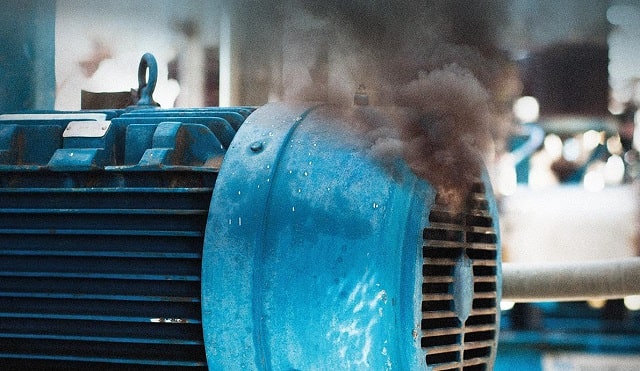

6. Safety Hazards.

Poor power quality can create safety hazards, such as flickering lights that can lead to eye strain or headaches, or more severe issues like electrical fires.

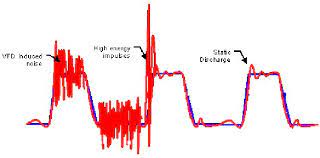

7. Interference with Communication Systems

Electrical noise can interfere with communication systems, including telephone and data networks, leading to poor signal quality or loss of connectivity.

8. Equipment Malfunction.

Power quality problems can cause equipment to malfunction, either by not working as intended or by shutting down completely, which can affect critical processes.

9. Product Quality Issues.

In manufacturing environments, power quality can affect the quality of the products being produced, especially if the equipment requires precise power levels to operate correctly.

10. Increased Operational Costs.

The cumulative effect of the above issues can lead to increased operational costs, including higher energy bills, more frequent equipment repairs, and additional investment in power quality mitigation equipment.

11. Legal and Regulatory Compliance Issues.

Certain industries have strict regulations regarding power quality, and failure to maintain those standards can result in fines or other legal consequences.

12. Reputation Damage.

Frequent power quality issues can damage a company’s reputation, especially if they lead to poor customer service or affect the quality of the products or services offered.

Addressing power quality issues proactively can help mitigate these consequences and ensure a stable and reliable power supply for the workplace.

From safety hazard to skyrocketing maintenance costs. we’ve got the expertise to fortify your business.

Call, Chat or Email Fullspectrum Solutions and start saving from today.